- #CASTING ENGINEER MAGMASOFT FULL#

- #CASTING ENGINEER MAGMASOFT SOFTWARE#

- #CASTING ENGINEER MAGMASOFT SERIES#

MAGMASOFT® reads and writes CAD information using neutral data formats and direct interfaces.

#CASTING ENGINEER MAGMASOFT FULL#

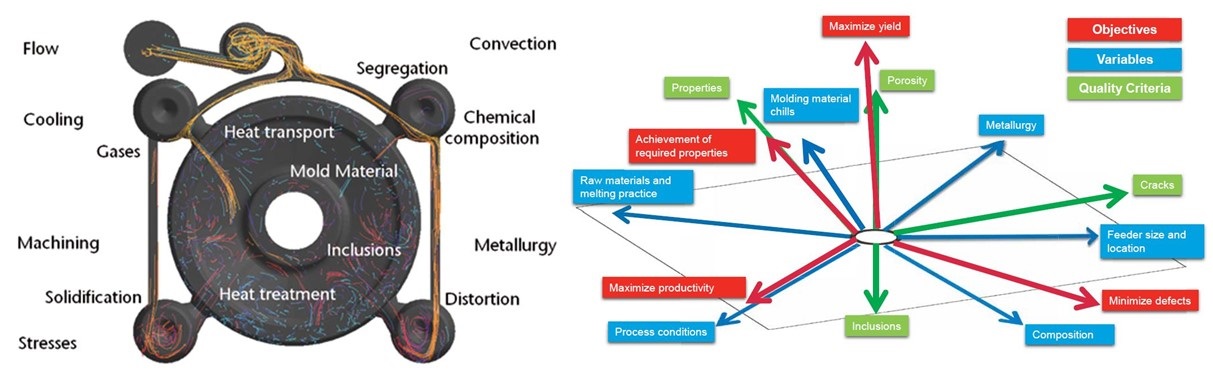

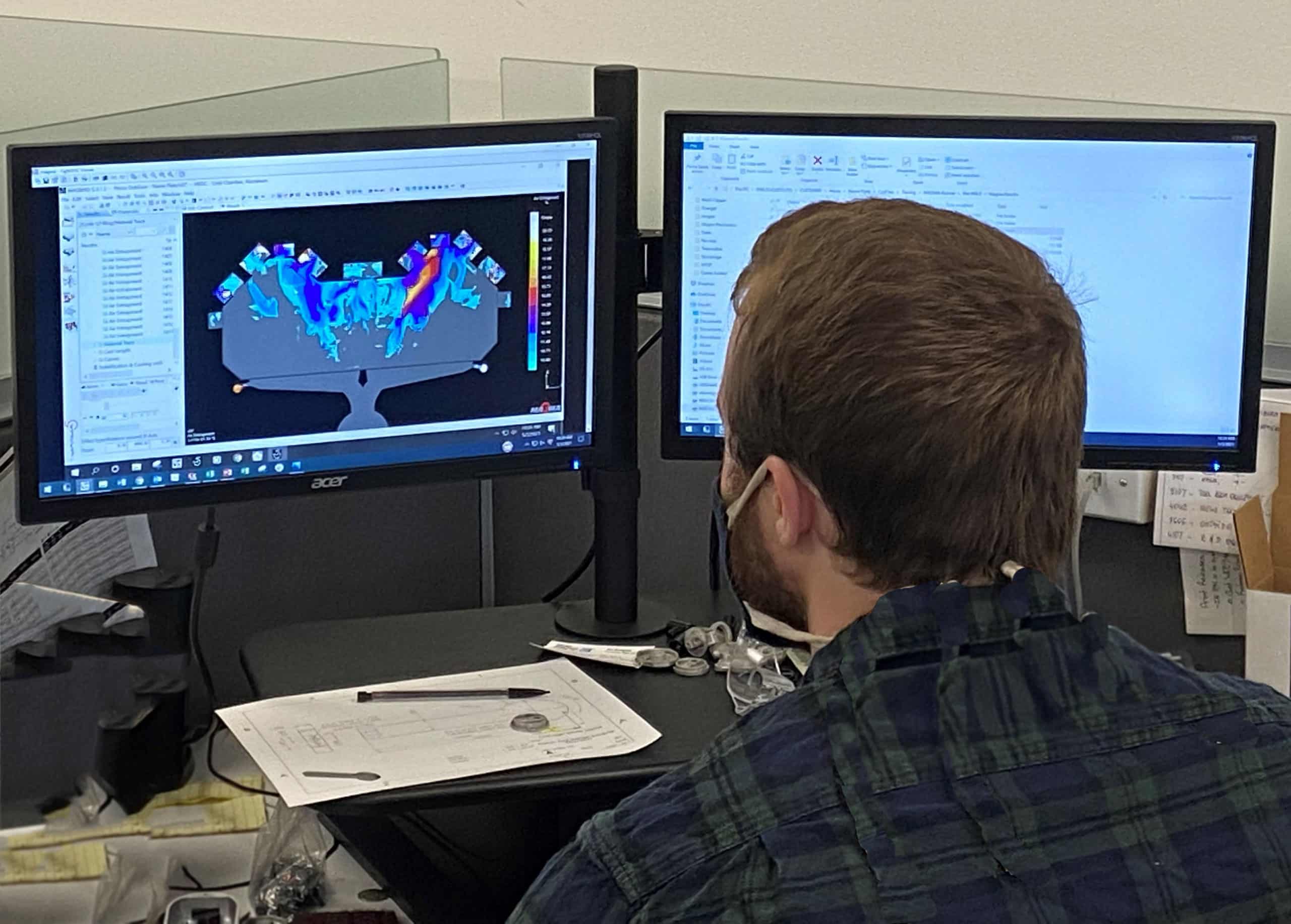

In this way, MAGMASOFT® is instrumental to secured decision-making and continuous improvement processes, ensuring the weight saving potential of cast part designs as well as reliable and robust production processes – exploiting the full potential of casting technology. The seamless integration of MAGMASOFT® into CAE environments delivers strategic and competitive advantages, by providing systematic knowledge on dependencies and variations of the manufacturing process in the early stages of conception and design. MAGMASOFT® allows risk assessment through virtual validation of product requirements against manufacturing robustness long before design approval. This enables casting designers and manufacturing experts to source and evaluate possible design options comprehensively and take secured decisions in an early development phase.

#CASTING ENGINEER MAGMASOFT SOFTWARE#

With MAGMASOFT®’s unique built-in methodologies for virtual Designs of Experiments and Autonomous Optimization, the software automatically runs and assesses various casting design and process parameter combinations. The integrated methodologies of MAGMASOFT ®, with the latest version MAGMA 5, facilitate the collaboration of casting designers and supply chain managers with experts from production – supporting Simultaneous Engineering or Integrated Product Development processes systematically, efficiently and intelligibly. Meeting other key criteria such as cost-effectiveness, resource efficiency, castability, process robustness and quality in a minimum of time presents fundamental challenges during the stages of component conception and design. The name MAGMA stands for robust and innovative casting solutions as well as a strong partnership with the. All planned and future appointments and services can be handled online/remote on request.The design process of cast components is driven by more than just functionality. MAGMA Engineering Asia-Pacific 783 MAGMA stands for robust and innovative casting solutions as well as a strong partnership with the metal casting industry MAGMA is a world-wide leading developer and supplier of software for casting process simulation. MAGMA Engineering supports you in the design of robust products and processes within your degrees of freedom.Īll contact persons from our company can be reached via the familiar communication channels, whether they work from one of our locations or from home office. No matter if it’s a simple solidification simulation, a full factorial experimental design or an autonomous optimization.

Potential solutions are document step by step.

#CASTING ENGINEER MAGMASOFT SERIES#

It is important to keep the economy running and to overcome the difficult challenges together. Ranking of the optimization results showing variables and quality criteria. In the ranking, design 1 offers the best compromise for all objectives with a minimized porosity, good mechanical properties and a low casting weight. We are currently in an extraordinary situation worldwide! ranking chart, the best compromise was found for the weighted quality criteria chosen. No matter if it’s short term, uncomplicated project service or systematic support as an extended workbench. Along this motto MAGMAengineering offers independent engineering and simulation services with MAGMASOFT for customers and non-customers.

0 kommentar(er)

0 kommentar(er)